Start up and Commissioning

Pharma-Tech Process and Facilities Services, LLC specializes in Start Up and Commissioning of small and large scale Biopharmaceutical Manufacturing and Medical Device production facilities. Unlike most commissioning agents out there today, we proactively commission and troubleshoot hardware and software issues in the field. We don’t just pencil whip documents or wait on the sidelines when a discrepancy or test fault is observed. We work with the owner and engineer to investigate the problem, suggest a solution and initiate a corrective action or change control immediately. Our past experience in design and operations of sanitary process equipment allows us to quickly move past issues that will delay construction, commissioning or qualification activities.

Our goal is to start up your facility to operate as intended by design and to meet the final user’s requirements. We will work with you to develop a commissioning plan that outlines the responsibilities of the design teams, construction contractors, commissioning agents and owner during the startup & commissioning phase. We have an extensive library of startup and commissioning templates and checklists that allow us to quickly apply our procedures and test plans to your specific project. We also identify the inspections and tests that can be leveraged into validation or qualification documents. This greatly minimizes document development time and allows for quicker document review, approval and field execution.

Poorly executed Commissioning efforts will result in delayed and costly validation and qualification activities.

Our Startup & Commissioning capabilities include:

- Start-Up and Commissioning Master Planning

- Criticality and Impact Assessment

- Risk Assessment and Mitigation

- Change Management

- Protocol Writing and Execution

- Installation Commissioning

- Operational Commissioning

- Standard Operating Procedures

- Factory and Site Acceptance Testing

- Maintenance Manuals

- Summary Reports

- Control System Testing and Troubleshooting

- Control Loop Tuning

- Cleaning Cycle Development

- Sterilization Cycle Development

- Engineering Runs

- Computer Software Commissioning

- Technical Writing

- Strategic Planning

- Traceability

- cGMP Documentation

- Standard Operating Procedures

- User Requirements

- Functional Specifications

- Detailed Design Specifications

- I/O Testing

- Alarms and Security Testing

- Process Analytical Technology

- Supplier Audit

- Factory and Site Acceptance Testing

- Quality Assurance

- GDP Review

- System walk downs

- Drawing and utility verification

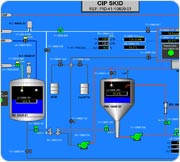

- Process and Facility Control System Operation and Troubleshooting. (Delta V, Allen Bradley, Siemens)

- Turnover package review and development

- Riboflavin coverage testing

- As-builts & Record Drawings

- ASTM E 2500

- Equipment Operation Training

- Automation Troubleshooting and Development

- Design Reviews

- DeltaV Users Training

- Passivation Coordination & Planning

- Create custom passivation procedures utilizing your CIP skid to batch and deliver passivation solutions to your process and clean utility equipment.