Cleanroom Containment Services

Pharma-Tech Process and Facilities Services, LLC is proud to offer portable containment products and services to control the spread of airborne particulate during construction, renovation and maintenance activities. Our innovative containment solutions are used to provide a temporary containment enclosure or barrier engineered to contain dust and debris during particulate generating activities normally not permitted in controlled environments during GMP manufacturing operations.

Portable Containment Enclosures are available for sale, service and rental. Cleanroom containment in 8 easy steps!

- STEP ONE

Transport containment materials to work area following client procedures for material entry and disinfection. (i.e. IPA, Spor-Klenz wipe down)

- STEP TWO

Erect containment enclosure, barriers and airlock around work area to be contained. If applicable setup fan powered HEPA filter to greater than 6 air change rates per hour and maintain a differential pressure of greater than 0.2” W.C.

- STEP THREE

Apply secondary gowning for entry into the cleanroom containment enclosure.

- STEP FOUR

Perform facility construction, renovation or maintenance activities requiring particulate containment.

- STEP

FIVE

Perform 3x cleaning on enclosure interior with ULPA HEPA vacuum and disinfectant of choice. (i.e. IPA, Spor-Klenz)

- STEP SIX

Remove secondary gowning and discard in provided bag out trash receptacle.

- STEP SEVEN

Doublebag trash receptacles and any additional items requiring containment during egress through the cleanroom.

- STEP EIGHT

Decommission, teardown and demobilize cleanroom containment enclosure. Bag out materials as necessary for additional protection of the cleanroom environment during egress.

Portable Cleanroom Containment Enclosures consist of the following main elements:

|

Poly-Frame - The Poly-Frame system is a 1.05” OD schedule 40 pipe extrusion designed to firmly snap and hold polysheeting to it. This system uses various fittings, couplers, tee’s, corners and crosses to erect a fast, durable and safe containment structures in virtually any size or shape without the need for tape, spray adhesives or zip poles. Available in both aluminum and PVC. |

|

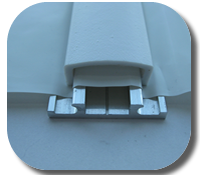

Poly-Flange - The Poly-Flange system is a custom flange extrusion designed to firmly snap and hold poly sheeting to it. This system can be used anywhere a strong continuous connection must be made between polysheeting and any flat horizontal or vertical building surface such as walls, doors, floors and ceilings. Available in both aluminum and PVC. |

|

Poly-Hangers - The Poly-Hangers are used to securely attach polysheeting to virtually any building surface. Several designs options are available to quickly and securely attach polysheeting to building surfaces such as equipment, ceiling grid, overhead objects, platforms, railings, piping, vessels, and conduit. Poly-Hangers are a tool in our containment toolbox that easily allows for custom containment configurations to align with field conditions. |

|

Polysheeting - The Polysheeting used to create our cleanroom containment enclosures is available in several options depending on the containment application and project requirements. Some options include: 1-12Mil thickness, Clear Polished Polysheeting, Flame Retardant and Anti-Static Polysheeting. |

|

Fan Powered HEPA/ULPA Filter - The Fan Powered HEPA/ULPA Filters used to create our differential pressure cleanroom containment enclosures are available in several different options and configurations depending on the containment application and project requirements. Fan sizing and filter selection are based upon the environmental classification, contaminants to be filtered and the volume of the containment enclosure boundary. |

|

Differential Pressure Monitoring - Differential Pressure Monitoring is used on any cleanroom containment enclosure to monitor, record and alarm if any pre established differential pressure conditions are not maintained. Calibrated differential pressure readings are time stamped and logged into memory once containment has been established. Audible and visual alarms activate whenever the pressure reaches the pre-configured alarm setpoints. Our differential pressure monitors are equipped with a thermal printer that provides a detailed, easy to read log of the pressure in the containment area as well as recording any changes made to the setup. Differential pressure logs can be printed and attached to Work Orders documenting negative pressure compliance during periods of particulate generating activities. Also available with WIFI adapter and cellular modem to automatically send alarm warnings and daily job summaries to wireless phones and email accounts |

Click here to for a printable version of our Cleanroom Containment brochure.

Web Mail Login | Toll Free: 1.866.797.0413

Copyright, © Pharma-Tech Process and Facilities Services, LLC, 2010